Post’s Niagara Falls Plant is one-of-a-kind – not only is it one of our oldest cereal manufacturing plants and neighbors one of the seven gorgeous wonders of the world, but it’s also known for its history rich in environmental stewardship and innovation.

Post’s Niagara Falls Plant has been a virtually 100% zero-waste-to-landfill manufacturing plant for over five years!

Over 43 million pounds of cereal are produced each year at this plant. We know, that’s a lot of cereal! It’s crucial we reduce our environmental impact on the planet by eliminating cereal and manufacturing waste that would otherwise end up in landfills.

Watch the video below or read on to meet Post employees committed to reducing food industry waste and get a closer look at our zero-waste processes in Niagara Falls.

What is a Zero-Waste-to-Landfill Manufacturing Plant?

Zero-waste-to-landfill refers to efforts that eliminate manufacturing and food waste from ending up in a landfill. Waste is eliminated by recycling or reusing it for other business operations, making it a sustainable practice that is mutually beneficial for the environment and Post’s future operations.

Reducing Food Waste Begins with Our People

When Mike Knapp, plant director at the Niagara Falls plant joined Post Consumer Brands 10 years ago, he asked if any other plants were zero-waste-to-landfill facilities. At that point, the answer was no.

The Niagara Falls team talked to its waste supplier, U-Pak, and they said it will cost a little more, but they can make it happen. Mike’s response was, “That’s okay, because it’s the right thing to do.”

Post’s Zero-Waste Processes and Procedures

Jo-Leen Honsinger, sanitation department employee, noted that the biggest challenges or concerns about it were how to get everyone on the team to separate materials correctly.

Following consistent sorting processes is key to ensure the most amount of waste is eliminated. We have plastic barrels, fiber and our cores. Everything gets sorted in specific locations in the plant without the separating and sorting. If that step is skipped, everything will just end up in the garbage.

We separate all the food ingredients into farmers’ feed. Cardboard and carton containers are separated for recycling. All electronics are also recycled. Any plastic barrels go back to the manufacturer for reuse, and pallets are recycled to a pallet company. Anything else that cannot be recycled (such as various plastic types and garbage) goes into incineration to be burnt.

Using these separation and incineration processes allows our plant to operate sustainably while giving back to the community.

Environmental Sustainability as a Team Effort

Our commitment to sustainability is why so many of our team members love being a part of the Post community.

Gino DiFrancesco is a 5S facilitator at our Niagara Falls Plant. He is responsible for zero-waste processes like sorting and organizing types of waste. “I think since I took on the 5S role, it’s really pushed me to make a difference and to make things better. I’m having fun with it,” says Gino.

“I think it’s definitely an exciting time to be with Post Consumer Brands and part of the Post Holdings family. There’s a lot of traction around sustainability initiatives,” says Bob Lambert, senior director, environmental health & safety.

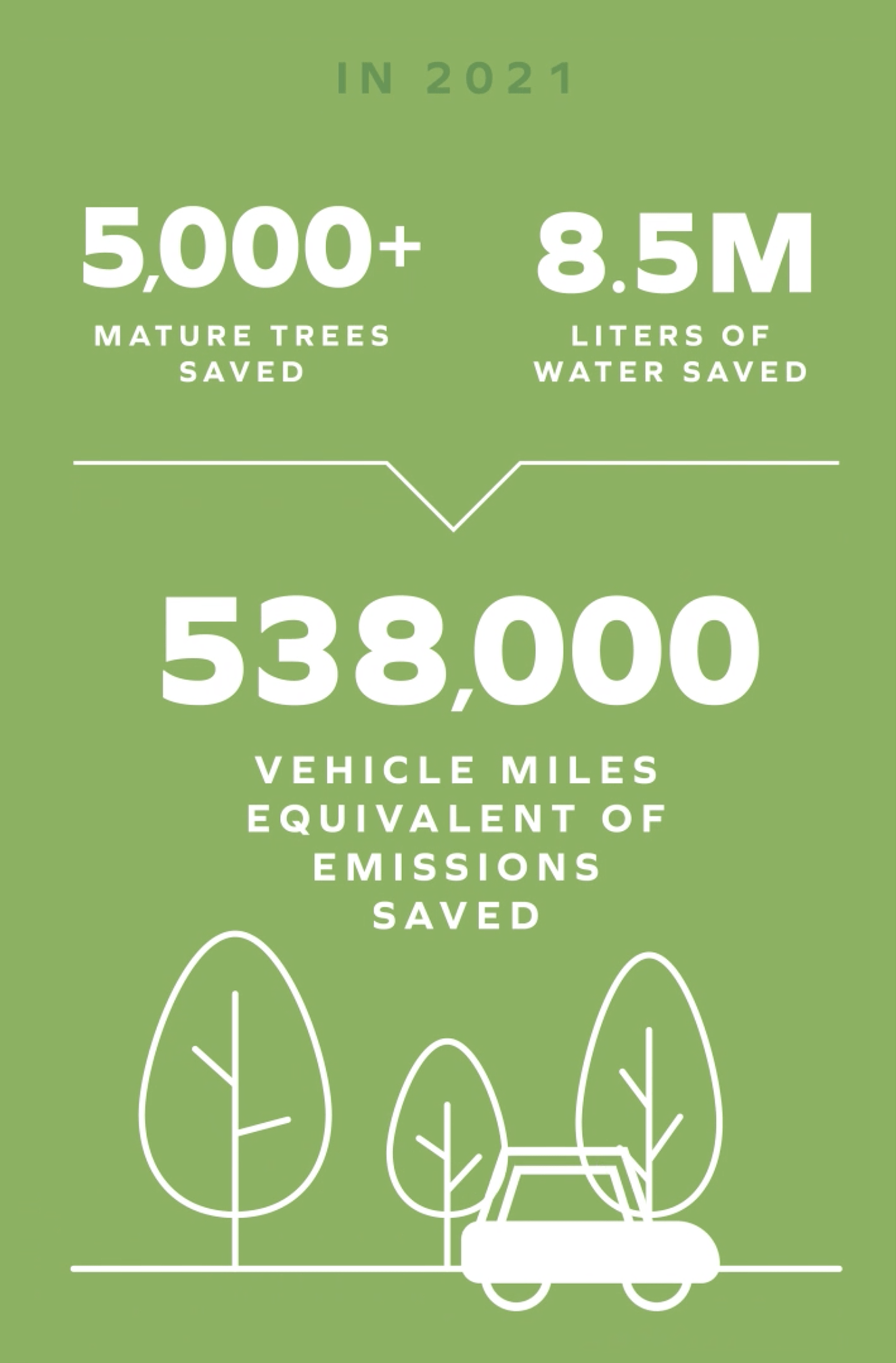

In 2021, at the Niagara Falls plant, the equivalent of over 5,000 mature trees and 8.5 million liters of water were saved. In addition, 538 million vehicle miles equivalent of emissions were saved from the plant’s operations. None of this would be possible without the commitment of our Niagara Falls employees!

It’s crucial for us to educate others around the importance of sustainability and why we need it for future generations. From alternative energy source usage to responsible sourcing, discover other ways we’re working to protect the environment.